Basic methods and precautions for heat energy recovery of air compressors

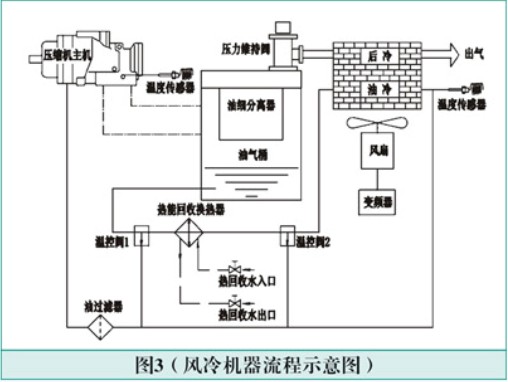

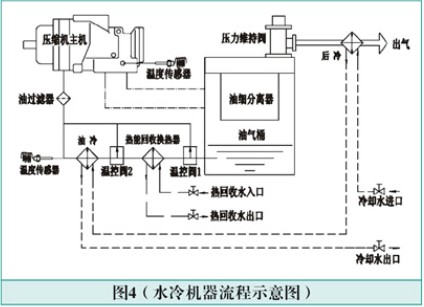

When the air compressor is cold started, the oil temperature is low, and the lubricating oil in the oil and gas barrel enters the machine head through the temperature control valve 1 and the oil filter. At this time, the heat recovery heat exchanger and the oil cooler are bypassed.

When the oil temperature rises to the temperature controlled by the temperature control valve 1, the lubricating oil flows into the heat energy recovery heat exchanger and transfers the heat to the water to be heated.

If the oil temperature after heat exchange is lower than the control temperature of the temperature control valve 2, the oil cooler is bypassed and enters the machine head through the oil filter. If the oil temperature reaches the control temperature of the temperature control valve 2, it will enter the oil cooling, and then enter the oil cooling machine head through the oil filter. If the oil temperature drops, the temperature control valve 1 and the temperature control valve 2 will judge in turn, This cycle repeats itself over and over.

(Schematic diagram of conventional heat recovery process of air-cooled air compressor)

(Schematic diagram of conventional heat recovery process of water-cooled air compressor)

When the bypass oil is cooled, the uniform fan operates at low frequency, and the air volume of the cooling fan is only used for cooling after cooling. If the oil temperature rises, the lubricating oil is cooled by the oil. At this time, some air compressors with larger power frequency operation port of the phoenix fan are equipped with two fans (F1, F2), the air compressor starts, F1 runs, and F2 The start/stop is controlled by the change of the exhaust temperature of the air compressor. When the exhaust temperature is too high and reaches the temperature control set value, F2 starts, and when the exhaust temperature drops to a certain temperature below the set value, F2 s. Installed on the F1 line. Water-cooled air compressors, such as water pumps and air compressors, are configured in one-to-one working conditions. The cooling water circuit can also be equipped with a water pump inverter, which can realize frequency conversion and speed regulation of the water pump according to the change of oil-cooled oil temperature. This design can save energy and reduce consumption.

Some enterprises have set up bypass valves on the oil pipelines of the heat recovery heat exchangers. When debugging and maintaining the air compressor, the heat recovery heat exchangers can be bypassed with the valves first. After the air compressors are properly debugged, the valves can be manually switched; no heat energy is required. During recovery, the heat energy recovery heat exchanger can be bypassed by the valve, which is basically the same as the ordinary air compressor. Some companies use electric valves to replace temperature control valve 2, and the control principle is basically the same.

Notes for air compressor heat recovery

Since the conventional heat energy recovery method of the air compressor uses the temperature control valve to control the lubricating oil flow, the structure is simple and the cost is low. JB/T6430-2002 "General Oil-Injected Screw Air Compressor" stipulates: "The low temperature of the compressed air should not be lower than its drop point temperature", which requires the exhaust temperature of the air compressor to be high (generally 75°C). ~95℃) to avoid the precipitation of water in the compressed air, the emulsification of lubricating oil and the reduction of oil life. The temperature control valve senses the change of oil temperature and can only be controlled at a fixed temperature. When the air compressor is running in a high temperature and high humidity environment, for example: ambient temperature 35°C, relative humidity 50%, exhaust pressure 0.8MPa (G), pressure dew point The temperature is 65°C. If the ambient temperature and relative humidity increase, it is difficult to avoid the precipitation of moisture in the compressed air. On the contrary, when the weather is cooler and the relative humidity is low, for example: the ambient temperature is 15°C, the relative humidity is 30%, the exhaust pressure is 0.8MPa (G), the pressure dew point temperature is only 31.5°C, and the air compressor with the temperature control valve is used. , the exhaust temperature is still maintained at a high value, the lubricating oil temperature is high, and the long-term operation will reduce the oil life.

Xiangyang Rongjingsheng Electromechanical provides you with heat energy recovery equipment for various air compressors and undertakes heat energy recovery projects

Rongjingsheng Electromechanical: Air compressor and aerodynamic energy saving experts around you 0710-3455557 13797571525

Official account QR code

Disclaimer: Some materials come from the Internet, if there is any infringement, please inform us to delete!