Nuts always come loose? Master these 6 little tricks, easy to solve

In mechanical design, a problem often encountered is: how to tighten a small nut. Like Japan's eccentric nut, Down's nut and China's self-tightening king nut, these are well known to everyone.

But we won't talk about these fastener industry stars today, let's talk about the basic method of fixing nuts at work.

Flat washer

Washer refers to the part between the connected piece and the nut. It is generally a flat metal ring, which is used to protect the surface of the connected piece from being scratched by the nut, and to disperse the pressure of the nut on the connected piece.

Flat and spring washers

Spring washers are widely used in load-bearing and non-load-bearing structures of general mechanical products, and are characterized by low cost and easy installation. , suitable for parts with frequent assembly and disassembly. But the anti-loosening ability of the spring washer is very low!

Self-locking nut

The general nut will loosen itself due to vibration and other reasons during use, such as vibration. In order to prevent this phenomenon, the self-locking nut was invented. The main functions of self-locking nuts are anti-loose and anti-vibration. For special occasions. Its working principle is generally self-locking by friction. The types of self-locking nuts classified by function include those with nylon rings, those with neck closures, and those with metal anti-loosening devices. They are all effective torque type locknuts.

Due to their nature, self-locking nuts are difficult to screw.

Nut anti-loosening fluid

Apply the nut anti-loosening liquid to the tightened part of the bolt, and then screw on the nut to achieve the effect of anti-loosening.

Double nuts (left and right) to prevent loosening

It is also a good method to tighten and prevent loosening by cooperating with a left-hand nut and a right-hand nut.

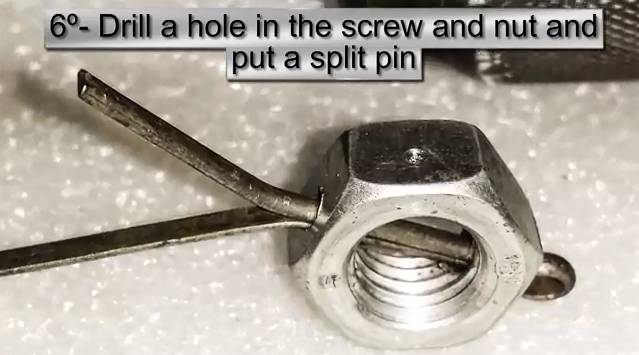

Screw and nut drilling and pinning< /strong>

In machinery, pins are mainly used for assembly positioning, and can also be used as overload shear connections in connection and relaxation level safety devices. The types of pins are: cylindrical pins, tapered pins, hole pins, cotter pins and safety pins.

- Previous:The principle is good for the cold dryer to remove water, but the reality is very interesting?

- Next:Already the last article

Official account QR code

Disclaimer: Some materials come from the Internet, if there is any infringement, please inform us to delete!