- SA Classic Series Micro Oil Screw Air Co...

- SA+ two-stage compression series screw a...

- SWV series oil-free screw air compressor

- SWT series oil-free screw air compressor

- P series centrifugal air compressor

- GTS series centrifugal air compressor

- Piston Reciprocating Air Compressor

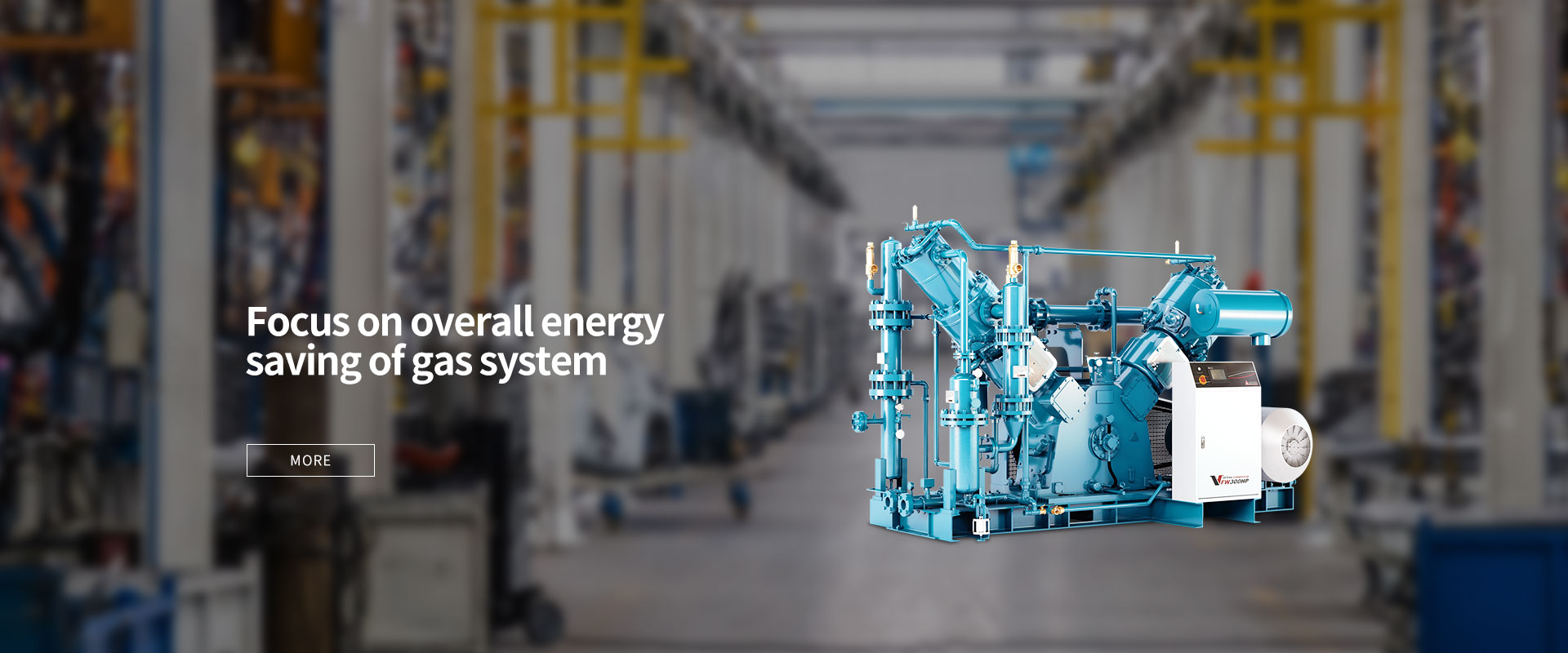

- VFW oil-free medium pressure air compres...

- GW series oil-free scroll air compressor

- refrigerant compressor

- Compressed air precision filter

- Compressed air dryer

- Compressed air adsorption dryer

Compressed air precision filter

EXHIBTION

Product show

DESCRIPTION

Product Description

Why use compressed air reprocessing equipment?

√ Compressed air is the second largest power source after electricity, and has a variety of process gas sources.

√ Most industrial compressed air operates at pressures of about 7, 10 or 13 barg, and purification and separation equipment is also typically designed around these jobs. Some application industries such as food, beverage, laser cutting, etc. require more working pressure. As the pressure increases, the concentration of pollutants in the compressed air will also increase.

√ Untreated compressed air also contains many potentially harmful and dangerous pollutants, these pollutants must be reduced to acceptable levels to protect the safety of users and improve the efficiency of enterprise production equipment and reduce operating costs.

√ If these potential contaminants are not controlled, companies may face prosecution.

√ HF series is aimed at the medium pressure requirements of laser cutting and other industries, solves the user's problems in the application of compressed air, and improves production efficiency;

Product Features & Advantages

1. All the shells are made of aluminum alloy die-casting, the structure is firm and the service life is long. All enclosures are cleaned, degreased, and anti-corrosion treated before painting;

2. Select a good filter material to reduce air flow and pressure loss, chemical corrosion, and have strong hydrophobicity and oleophobicity;

3. 96% porosity of dust holding capacity, service life up to 6000-8000 hours, pressure loss 0.17-0.65 bar;

4. Double support mesh to ensure the strength of the elements and protect the fiberglass material.

5. The new parallel design reduces installation and maintenance space, and can be fixed on the wall;

6. Filter grades PF, AO, AA, ACS, AX, AR, AAR comply with ISO8573.1-2010 standard;

7. FPM sealing ring improves air tightness and achieves better filtration performance;

8. The top cover made of PA + GF material can withstand the temperature of 240℃, can resist general acid and chemical corrosion, and has strong hydrophobicity and oleophobicity;

9. 96% porosity of dust holding capacity, service life up to 6000-8000 hours, pressure loss 0.17-0.65 bar;

10. Double support mesh to ensure the strength of the elements and protect the fiberglass material.

ADVANTAGE

Product advantages

-

Sturdy construction

All the shells are made of aluminum alloy die-casting, with a solid structure and long service life. All enclosures are cleaned, degreased, and anti-corrosion treated before painting

-

Material is guaranteed

Select good filter material to reduce air flow and pressure loss chemical corrosion, with strong hydrophobicity and oleophobicity

-

long life

96% porosity of dust holding capacity, service life up to 6000-8000 hours, pressure loss 0.17-0.65 bar;

SPECIFICATION SELECTION

Specification selection

ONLINE INQUIRY

在线询盘

ONLINE INQUIRY

Official account QR code

Disclaimer: Some materials come from the Internet, if there is any infringement, please inform us to delete!