How to choose a suitable screw air compressor

Below, Rongjingsheng Electromechanical will answer some of your concerns.

1. Choose the right air compressor

First of all, users should first calculate the compressed air volume required by their own equipment, and generally reserve a 15%-20% margin on the calculated air volume.

3. Choose the right air purification equipment

We know that there is a lot of dust and moisture in the air. According to your own equipment needs, you can choose to use a freeze dryer or an adsorption dryer, and a suitable air precision filter to achieve the level of compressed air suitable for your own process.

4. Choose an air compressor with a higher energy efficiency level

At present, according to the relevant national standards, air compressors have three energy efficiency levels, and there will be an energy consumption difference of about 8% between each energy efficiency level. If the budget is appropriate, it is more energy-saving to choose a product with first-level energy efficiency.

Rongjingsheng Electromechanical provides you with screw air compressors with better energy efficiency standards.

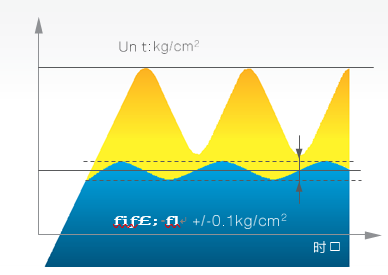

5. Try to choose inverter models

In fact, the compressed air demand of most customer factories is constantly changing. The use of variable frequency air compressors can ensure that as much compressed air as the user uses, as much compressed air is generated, reducing the no-load time of the air compressor, which can also greatly of energy saving.

At the same time, as we mentioned above, what the user actually needs is the pressure (low pressure) when the air compressor is loaded. When the outlet pressure of the air compressor increases by 0.1Mpa, 7-8% more electric energy is consumed, and the frequency conversion air compressor is used. , the output pressure of the air compressor can be accurately maintained within the range of ±0.01Mpa required by customers, which greatly saves energy.

- Previous:Already the first article

- Next:How to solve the high temperature of the air compressor

Official account QR code

Disclaimer: Some materials come from the Internet, if there is any infringement, please inform us to delete!