Basic knowledge of air compressor ---- twin screw air compressor

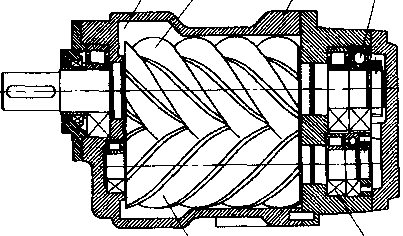

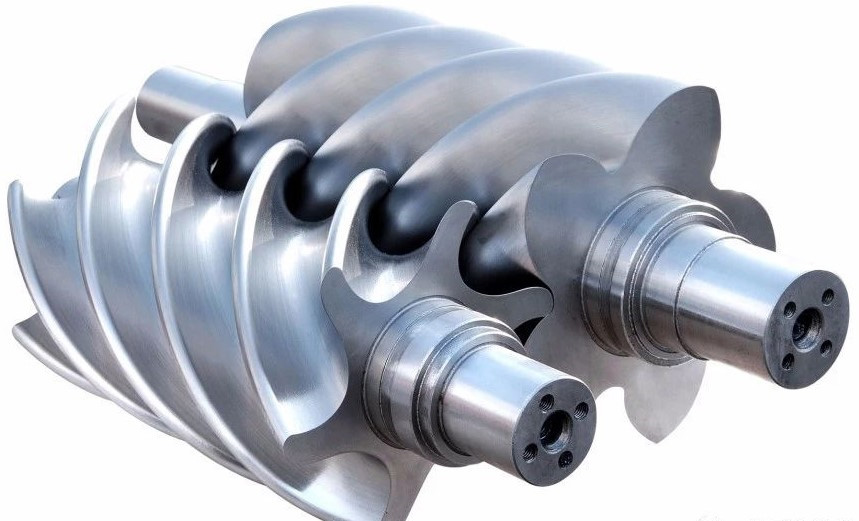

Most screw air compressors are of twin screw structure

In the body of the compressor, a pair of helical rotors meshing with each other are arranged in parallel.

Usually, the rotor with protruding teeth outside the pitch circle is called the male rotor, and the rotor with concave teeth inside the pitch circle is called the female rotor. The male rotor is usually connected with the prime mover to drive the female rotor to rotate, the male rotor is active, and the female rotor is driven.

The compressor will generate large axial and radial forces during operation. Usually, ball bearings are used to withstand axial forces and axial positioning, and cylindrical roller bearings are used to withstand radial forces and radial positioning.

At both ends of the compressor body, intake and exhaust ports are opened. One is for suction, called the suction port; the other is for exhaust, called the exhaust port.

Working principle of twin screw air compressor

The rotor rotates in the casing which is precisely matched with it, so that the gas between the rotor slots continuously produces periodic volume changes and is pushed from the suction side to the discharge side along the rotor axis. This repeated volume change realizes the working process of the compressor compressing the gas.

Advantages of screw compressors

1. High reliability. The screw compressor has few parts and no wearing parts, so it operates reliably, has a long service life, and the overhaul interval can reach 40,000 to 80,000 hours;

2. Easy to operate and maintain. Operators do not have to undergo long-term focused training, and can achieve unattended operation;

3. Good dynamic balance. The screw compressor has no unbalanced inertial force, the machine works smoothly at high speed, and can realize no foundation operation. It is especially suitable for use as a mobile compressor, with small size, light weight and small footprint;

4. Strong adaptability. The screw compressor has the characteristics of forced gas delivery, the displacement is almost not affected by the exhaust pressure, and it can ensure high efficiency in a wide range;

5. Multiphase mixed loss. There are actually gaps between the rotor teeth of the screw compressor, so it can withstand liquid impact, and can be pressurized to send liquid-containing gas, dust-containing gas, and easily polymerized gas.

Classification of screw compressors

According to different operating modes, it is divided into oil-free compressors and oil-injected compressors;

According to the different types and uses of compressed gas, it is divided into three types: air compressor, refrigeration compressor and process compressor;

According to different structural forms, it is divided into mobile and fixed, open and closed.

Fusheng screw air compressor

Fusheng is currently a world-renowned manufacturer of screw air compressors. There are more than a dozen compressor factories in the United States, Germany, Mainland China, Taiwan, Southeast Asia, South America, etc.

Its screw air compressors have obtained a number of global patents.

Its products: leading technology, reliable quality, excellent service

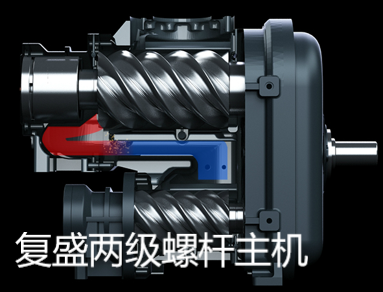

Fusheng to energy-saving two-stage screw air compressor

Fusheng's two-stage screw air compressor has an energy efficiency ratio superior to my country's first-class energy efficiency standard in many aspects.

It is the screw air compressor with the lowest power consumption on the market.

After several years and thousands of applications, the reliability is well-known.

For specific products, please contact Rongjingsheng Electromechanical: 0710-3455557 13797571525

Rongjingsheng Electromechanical: Air compressor and aerodynamic energy saving experts around you

Official account QR code

Disclaimer: Some materials come from the Internet, if there is any infringement, please inform us to delete!