Basic knowledge of air compressor - centrifugal air compressor

•Centrifugal compressors are generally applicable to: flow/pressure 100~2000m³/min, 0.07~70MPa;

Centrifugal type belongs to the category of speed type (also called power type) compressor. compressor.

In the early days, centrifugal compressors were mainly used to compress air, and were only suitable for medium and low pressure and atmospheric volume applications. However, with the application of new technologies, new processes and new structures, the pressure has been applied to the high-pressure field, and the flow has been developing towards larger and smaller flows.

Fusheng's American factory - Elliott, established in 1898, is the world's largest factory with centrifugal air compressors.

The structure of "centrifugal" is a generalist, such as centrifugal pump, centrifugal fan, centrifugal blower, etc. The similarity of these structures is that they all have an impeller (blade) and a volute.

Centrifugal compressors are used to compress other gases, such as syngas, cracked gas, carbon dioxide, etc. Some gas compressors are different in structure, so I won't discuss them here.

Centrifugal compressors are divided into three structures according to the structure and transmission mode: horizontal split type, vertical split type (also known as cylinder type) and isothermal type. The first two refer to the cylinder split method on the structure, and the latter The main difference between the two is the use of interstage cooling, most of which are multi-axis structures.

• The cylinder of horizontal split type is split into upper and lower parts, which are fastened with bolts and easy to disassemble. Generally used for low and medium pressure air compressors, not suitable for high pressure and oxygen-rich gas with small molecular weight. Most single-stage centrifugal air compressors are of this structure.

Centrifuges offer the following benefits:

①Large production capacity and uniform air supply;

②Compared with the piston machine, the structure is simple and compact, the floor area is small, and the civil construction investment is less;

③ Fewer wearing parts, easy maintenance and reliable operation. In particular, the continuous operation cycle is long, and the workload of operation and maintenance is less;

④ There is no contact friction between the rotor and the stator except the bearing and the shaft end seal;

⑤ No lubrication (no oil) in the cylinder is required for a wide range of applications.

Main disadvantages of centrifuges:

①Comparison rate is only available when working under the design conditions, the efficiency will drop away from the design conditions, and the ability to change working conditions will be poor;

②The single-stage pressure ratio is low, and it is not easy to obtain a small flow rate at the same time as the high pressure ratio. This is mainly because the flow rate is small and the airflow channel is narrowed, so the manufacturing process is difficult, the flow loss of compressed air is large, and the efficiency is very low;

③ The adaptability of the operation is relatively poor, and the properties of the gas have a great influence on the operation performance.

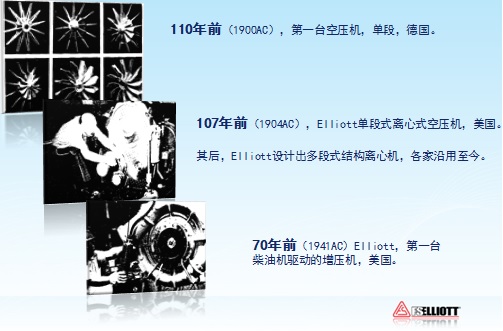

Elliott Ltd. has a rich history dating back 110 years. Elliott's foundation was laid in 1895, when a young engineer named Williman Swan. Elliott acquired a water pump and a deep-water rod cleaning head and applied it to the fouling of boiler pipes. Elliott moved its headquarters from Chicago to Janet, Pennsylvania in 1914. Two years later, the acquisition of Lagenda Manufacturing allowed Elliott to expand its business and manufacturing of pipe cleaning equipment.

In 1924, Elliott resolutely purchased the Kerr Turbomachinery Company and began ELLIOTT's nearly 100-year turbomachinery manufacturing. Elliott purchased Ridgway Power Machinery in 1926, and the engine and compressor line complemented Elliott's turbomachinery line and in the same year strengthened its Janet City-based compressor and turbomachinery production.

In 1941, Elliott Company manufactured a turbocharger driven by a diesel engine in the United States. At the same time, in 1942 all Elliott factories were converted to production, and were rated as "E" grade enterprises (E is) by the Army and Navy. In 1957 Elliott became one of the Carrier joint ventures.

In 1962, Elliott Company produced the world's first factory-type PAP centrifugal air compressor.

In 1967, Elliott Overseas Company was established, marking that Elliott became a multinational company, and its products were sold to different regions. In 1968, the Japanese Ebara Manufacturing Company obtained a production license to manufacture turbomachinery products designed by Elliott.

In 1975, the world's pressure-removing (654bar) centrifugal compressor was produced. In 1979 the Carrier joint venture became a subsidiary of the Federal Institute of Technology. The world's largest pressure expander (35,000HP) was produced in 1980. This expander was designed and built by Elliott for the Texas refinery.

In 1998, Elliott Group jointly invested and established Fusheng Yilida (Shanghai) Compressor Co., Ltd. in mainland China and Taiwan Fusheng Group. In 2001, Fusheng Yilida (Shanghai) Compressor Co., Ltd. PAP series centrifugal air compressor spare parts repair factory was established in Shanghai Songjiang Development Zone, becoming one of several manufacturers that mainly produce centrifugal air compressors in the world. Companies established in mainland China.

Rongjingsheng Electromechanical--Air compressor and aerodynamic energy saving experts around you 0710-3455557 13797571525

Official account QR code

Disclaimer: Some materials come from the Internet, if there is any infringement, please inform us to delete!